Lightweight Materials in Automotive Design and Manufacturing

The automotive industry continuously seeks innovative ways to enhance vehicle performance, fuel efficiency, and overall sustainability. A key area of focus in this pursuit involves the strategic integration of lightweight materials into both design and manufacturing processes. By reducing the overall mass of a vehicle, engineers can achieve significant improvements across various critical metrics, impacting everything from driving dynamics to environmental footprint, which is crucial for the future of transport and mobility.

What Are the Key Lightweight Materials Used in Automotive Engineering?

The evolution of automotive engineering has seen a steady shift towards materials that offer a superior strength-to-weight ratio. High-strength steel alloys are foundational, providing excellent crash performance while allowing for thinner gauges. Aluminum, widely used in body structures, engine blocks, and wheels, offers substantial weight savings compared to traditional steel. Carbon fiber reinforced polymers (CFRPs) represent a more advanced class of materials, prized for their exceptional stiffness and strength at very low densities, often found in high-performance or electric vehicle components. Magnesium alloys are another contender, even lighter than aluminum, typically employed in smaller, complex castings like transmission cases or instrument panel beams, contributing to overall vehicle lightness.

How Do Design and Technology Drive Lightweight Innovation?

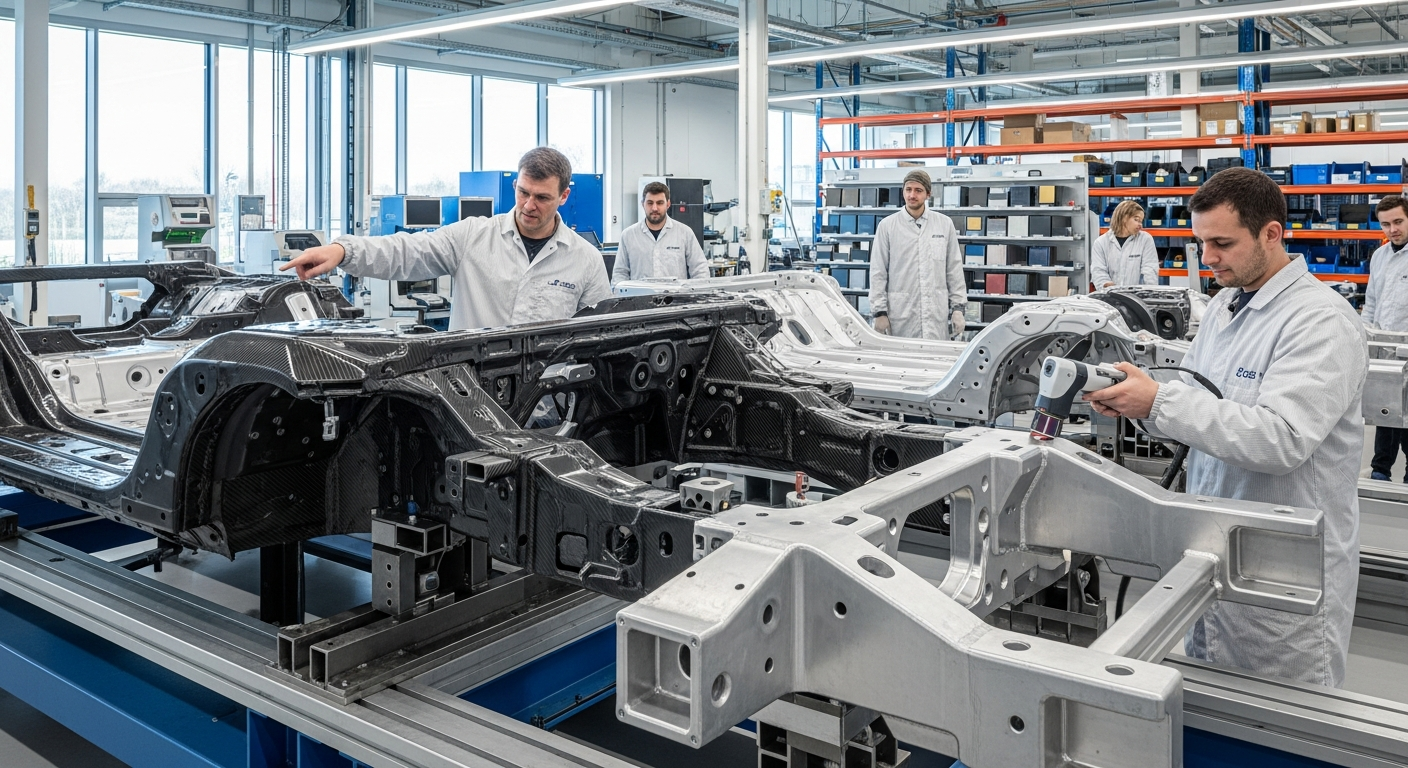

Achieving effective lightweighting goes beyond simply substituting heavy materials with lighter ones; it requires a holistic approach encompassing advanced design principles and cutting-edge technology. Modern automotive design leverages sophisticated computer-aided design (CAD) and simulation software to optimize part geometry, ensuring structural integrity while minimizing material usage. Manufacturing innovation plays a crucial role, with techniques such as hydroforming for complex aluminum parts, advanced joining methods like adhesive bonding and laser welding for dissimilar materials, and even additive manufacturing (3D printing) for intricate, optimized components. These technological advancements enable engineers to create structures that are not only lighter but also stronger and more efficient in their material use, enhancing the overall systems of a vehicle.

What Impact Do Lightweight Materials Have on Vehicle Performance and Electric Mobility?

The benefits of lightweight materials extend significantly to vehicle performance. A lighter vehicle requires less energy to accelerate, brake, and navigate, directly translating into improved fuel efficiency for internal combustion engines and extended range for electric vehicles. Reduced mass also enhances the driving experience by improving handling, responsiveness, and agility. This is particularly critical for electric vehicles, where battery weight is substantial; lightweight body structures and components help offset this, maintaining competitive performance metrics and supporting the broader shift towards sustainable mobility solutions. Enhanced performance also means better power-to-weight ratios, contributing to a more dynamic and engaging driving experience.

How Do Lightweight Materials Contribute to Vehicle Safety Systems?

One common misconception is that lightweight materials compromise safety. In reality, modern lightweight materials are engineered to enhance vehicle safety. High-strength steels and advanced composites are designed to absorb and dissipate crash energy more effectively than older, heavier materials. Through sophisticated engineering, these materials can be strategically placed to create crumple zones that deform predictably in an impact, protecting the occupant compartment. This allows for the integration of advanced safety systems, ensuring that lighter vehicles meet or exceed stringent global safety standards. The combination of innovative material science and intelligent structural design ensures that vehicles remain robust and secure.

Considering the Future of Lightweighting for Transport and Mobility

The trajectory of lightweight materials in automotive manufacturing is set to continue evolving, driven by demands for greater sustainability, efficiency, and the advent of autonomous vehicle technology. Future developments may include the wider adoption of bio-based composites, advanced thermoplastic composites, and smart materials that can adapt their properties. The integration of artificial intelligence and machine learning in material selection and design optimization will further refine lightweighting strategies. As autonomous systems become more prevalent, the structural requirements for vehicles may shift, potentially allowing for even more radical lightweight designs that prioritize passenger comfort and novel interior layouts, defining the future of transport and urban mobility.

The strategic application of lightweight materials is a cornerstone of modern automotive engineering, providing multifaceted benefits from enhanced performance and fuel efficiency to improved safety and sustainability. As the industry continues to innovate, the role of these advanced materials will only grow, shaping the future of vehicles and contributing significantly to the broader goals of efficient and environmentally responsible transport.